Stone Panels

Outline

– The big idea: why stone panels matter for modern homes

– Design possibilities: textures, formats, and room-to-room versatility

– Performance: durability, moisture, thermal comfort, acoustics, and fire

– Installation and cost: planning, methods, timelines, and budgeting

– Sustainability and lifecycle value

– Real-world applications, care, and a practical conclusion

Introduction

Stone panels are quietly reshaping how homeowners approach remodeling and new builds. They carry the charm of natural materials yet fit the fast pace of contemporary construction, offering visual warmth without the structural baggage of full-thickness masonry. Whether you’re planning a dramatic fireplace wall, a durable shower enclosure, or an exterior facelift, panels compress timelines and simplify logistics. The result is a design-forward solution that balances aesthetics, performance, and value across interior and exterior spaces.

Design Freedom: Aesthetic Range and Room-to-Room Versatility

If you’ve ever watched sunlight rake across a textured wall, you know how much surface matters. Stone panels lean into that magic, offering formats and finishes that make small rooms feel intentional and large rooms feel grounded. Options span thin-cut natural stone veneer, reconstituted mineral composites, concrete-based claddings, and large-format sintered surfaces. Each brings a slightly different mood: the organic variation of natural splits, the disciplined consistency of engineered textures, the crisp edges of honed faces, or the inviting softness of tumbled profiles.

Colorways are equally broad. From cool grays and silvers for minimal schemes to sun-warmed beiges and russets for rustic atmospheres, panels allow you to carry a coherent palette through kitchens, entryways, living rooms, and patios. Formats range from tight linear “ledgestone” looks to larger ashlar patterns and monolithic slabs that minimize joint lines. Many systems include prefabricated corners, which tidy up edges where traditional tile or stacked stone might look piecemeal.

Compared with full-depth masonry, panels reduce weight dramatically, which means fewer structural upgrades and more freedom to use stone in places you might have ruled out—upper floors, lightweight partitions, or aging substrates that need a gentler load. That opens creative doors:

– Run a continuous stone accent from foyer to stairwell without beefing up framing.

– Wrap a kitchen island with impact-resistant panels that take bumps better than painted drywall.

– Add a textured backsplash behind open shelving to highlight everyday objects with shadow and contrast.

The result is a toolkit that can skew rustic, industrial, or refined without feeling contrived. Because panels repeat less predictably than printed laminates and reflect light differently than paint, they create depth even in compact spaces. For homeowners chasing a signature element that isn’t overpowering, stone panels strike a balanced note—characterful but calm, tactile yet easy to live with.

Performance in Daily Life: Durability, Moisture, Thermal Comfort, Acoustics, and Fire

Beyond looks, stone panels earn their keep through solid performance. Many natural stone veneers offer compressive strengths readily above 50 MPa, while dense sintered surfaces and concrete-based options resist abrasion and everyday knocks. Surface hardness varies: honed and polished faces shrug off splashes and wipe clean; textured splits disguise minor scuffs from luggage wheels or pet traffic. Porous stones may benefit from a penetrating sealer; applied properly, maintenance usually boils down to mild soap, soft brushes, and occasional reapplication per manufacturer guidance.

Moisture is a common worry, especially in showers and exterior walls. Panels address this with two complementary strategies: a stable, water-resistant substrate and, for exteriors, a ventilated rainscreen or drainage plane. Small gaps let incidental moisture escape, reducing the risk of trapped condensation. Freeze–thaw durability depends on material density and absorption; many panel systems are tested to cycling standards and are intended to resist spalling when installed over proper flashing and weather barriers. Indoors, properly detailed shower assemblies direct water to drains and keep substrates dry.

Thermally, stone is a poor insulator but an effective thermal mass. It won’t replace cavity insulation, yet it can moderate short-term temperature swings by absorbing warmth and releasing it slowly. Pairing panels with continuous exterior insulation or insulated backer boards helps meet energy targets without sacrificing the tactile finish. Acoustically, adding mass to a wall can trim ambient noise; while gains vary by assembly, it’s reasonable to expect a modest improvement in perceived sound transmission when a dense cladding is added to lightweight partitions.

Fire performance is another advantage. Mineral-based panels are typically noncombustible or achieve high fire ratings, an important consideration around fireplaces and in multifamily settings. Polymer-containing products may carry different ratings; always check local codes and product documentation for clearances and substrate requirements. Lastly, indoor air quality is frequently cited: stone and mineral composites are inert and generally low-VOC, supporting healthy interiors when paired with appropriate adhesives and sealants.

Installation and Cost: Planning, Methods, Timelines, and Budgeting

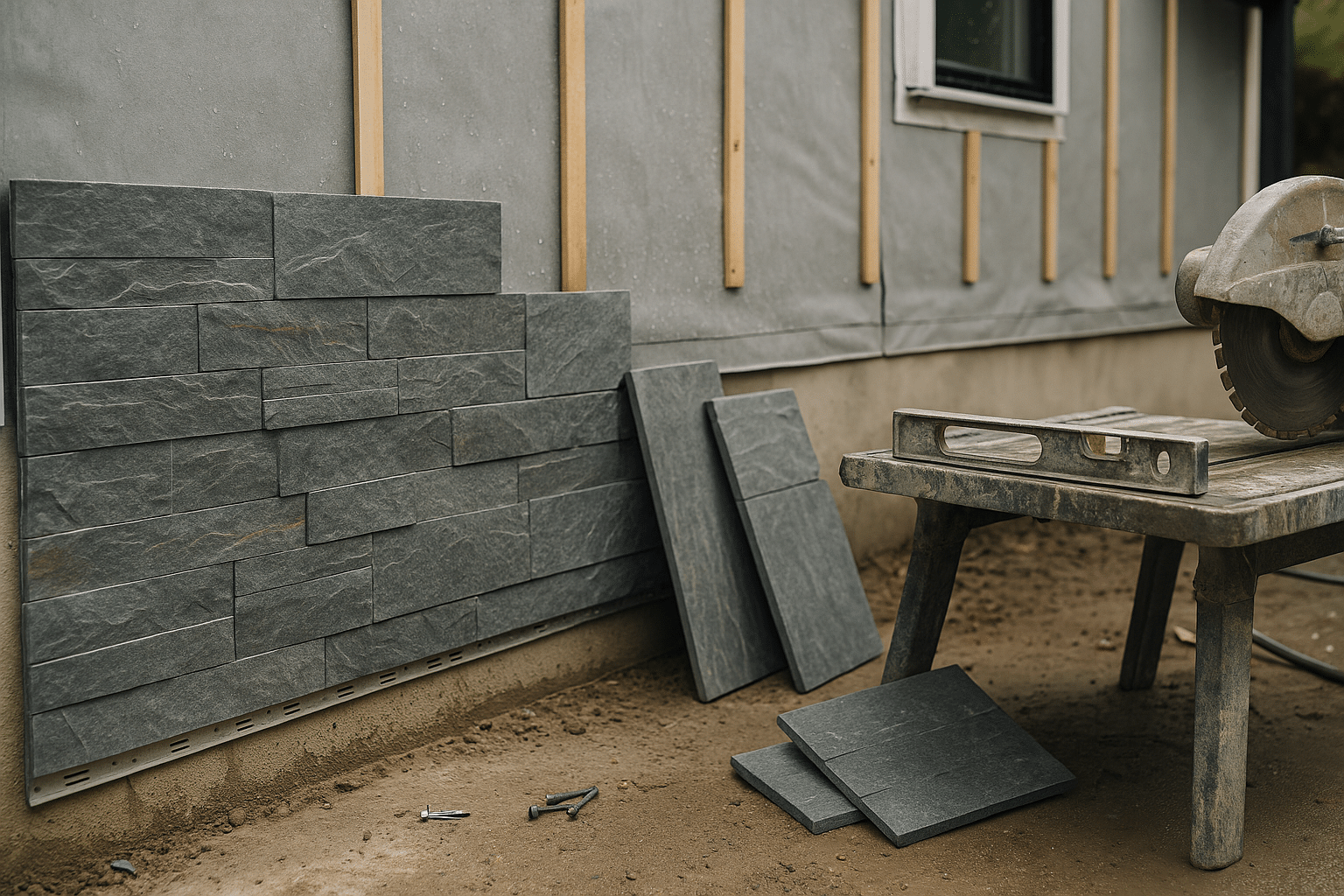

Good results start with a clear plan. Indoors, you’ll confirm substrate flatness, mark control lines, dry-fit courses, and stage corner pieces. In wet areas, waterproofing membranes and sloped surfaces are non-negotiable. Outdoors, a rainscreen approach with a weather-resistant barrier, furring, flashing at openings, and weeps at the base helps panels shed water. Some systems use mechanical clips or anchors; others are adhered with mortars or construction adhesives designed for the substrate and environment.

Cutting is typically done with a diamond blade and dust management, especially for dense or sintered materials. Layout is where design meets craft: balance joint lines, avoid slivers at edges, and integrate outlets and fixtures. Prefabricated corners produce continuous-looking returns; field-mitering is possible with care and the right tools. Grout joints or tight-stack looks change the vibe: grouted assemblies read classic and forgiving, while tight-stack feels crisp but demands truer substrates and sharper tolerances.

Time savings compared with full-depth masonry can be significant. Panels are lighter to lift and often install with fewer layers. On straightforward interior accent walls, a competent crew might complete in a day what would otherwise spill into several, depending on pattern complexity. Exterior cladding requires more sequencing—flashings, ventilation gaps, and joint details—but still typically beats the labor hours of hand-laid, full-bed stone.

Budgeting depends on material, region, and scope. As broad, location-sensitive ranges:

– Thin natural stone veneer installed might fall in the vicinity of $18–$35 per sq ft.

– Engineered or concrete-based panels often land around $12–$28 per sq ft.

– Large-format sintered surfaces and premium formats can run $35–$60+ per sq ft.

These figures include typical labor but exclude substrate corrections, scaffolding, complex detailing, or premium sealers. To keep surprises at bay, plan a small contingency and request line-item quotes that distinguish material, prep, and finish steps.

Common pitfalls to avoid:

– Skipping substrate flatness checks, which telegraph as uneven joints.

– Underestimating corner needs, leading to mismatched edges.

– Neglecting expansion and control joints on large runs.

– Using harsh cleaners that etch or haze certain finishes.

Get these fundamentals right, and installation is remarkably approachable, with a satisfying blend of speed and craft.

Sustainability and Lifecycle Value: Material Footprint, Longevity, and Repairability

Sustainability with stone panels starts with mass. Reducing thickness and weight lowers transport energy per square foot compared with full-depth blocks, which can translate into fewer trips and smaller lifting equipment. Many mineral-based products have long service lives, and durability is a quiet form of sustainability: materials that resist wear, water, and UV simply need replacing less often. When repair is needed, panels make it practical to swap a single damaged unit rather than rebuild a larger area.

Embodied carbon varies by material. Natural stone often benefits from low-temperature processing—quarrying, cutting, finishing—though long-distance transport can offset some advantages. Cement-based products carry the emissions profile of their binders but may include recycled aggregates or supplementary cementitious materials to reduce impact. Sintered surfaces are energy intensive during firing yet durable and stable once installed. The takeaway is nuanced: consider both product and logistics, and weigh decades of use against the upfront footprint.

Operational energy also enters the picture. Panels themselves don’t insulate much, but they integrate cleanly with exterior continuous insulation and air barriers, improving whole-wall performance. Inside, the thermal mass effect can smooth spikes from sun or cooking heat. Longevity supports resource efficiency; finishes that still look composed after ten years reduce the urge to redecorate prematurely, cutting waste from repeated remodels.

Responsible sourcing is worth a question or two. Look for suppliers that document quarry practices, water recycling in fabrication, and dust control. For concrete or composite options, ask about recycled content and take-back programs. At end of life, intact stone can be reclaimed for landscapes or smaller interior features, and broken offcuts can serve as fill or garden edging. Sustainability isn’t a single metric—it’s a chain of decisions—which is why panels that enable durable, low-maintenance assemblies often offer strong lifecycle value.

Applications, Care, and Conclusion: Bringing Stone Panels into Everyday Spaces

Real homes benefit from solutions that work as well as they wow. Consider these application ideas:

– Living room: a fireplace surround in split-face veneer that catches evening light without overwhelming the room.

– Kitchen: a honed backsplash or island cladding that tolerates splashes and wipes clean.

– Entry or hallway: a narrow accent wall that adds depth where floor space is tight.

– Bath: moisture-tolerant panels over waterproof substrates for a spa feel, with slip-resistant textures in wet zones.

– Exterior: a front facade upgrade that frames windows and doors with crisp returns and durable edges.

– Outdoor kitchen: stain-resilient panels paired with stainless or stone countertops for a cohesive, weatherworthy station.

Maintenance is refreshingly straightforward. Start with a gentle cleaner—neutral pH soap and water—plus soft pads or brushes. Rinse well, especially on textured splits where residue lingers. For porous stones, a breathable penetrating sealer helps resist oil and dye transfer; frequency depends on exposure, but many interiors go several years between applications. On exteriors, inspect sealant joints and flashings annually, clear debris from weeps, and rinse off de-icing salts as winter recedes. If efflorescence appears as a white bloom, address moisture sources first, then use a product formulated for mineral surfaces.

Repairs are practical. Because panels are modular, an isolated chip or crack doesn’t mean starting over; sections can be removed and replaced with careful cutting at joints. Keep a few spare pieces from the original batch to maintain color consistency. Indoors, felt pads on furniture and soft bumpers on high-traffic corners go a long way. Outdoors, mind clearance from grade to prevent splash-back staining and consider drip edges under caps to steer water away from faces.

Conclusion: For homeowners and renovators seeking a mix of character, durability, and efficient installation, stone panels are a compelling path. They bring the tactile richness of masonry into places where weight, time, or budget would otherwise say no. With thoughtful detailing—sound substrates, sensible moisture design, and routine care—they deliver stable performance indoors and out. If your next project calls for a natural-feeling finish that respects schedules and dollars, panels deserve a spot high on the shortlist.